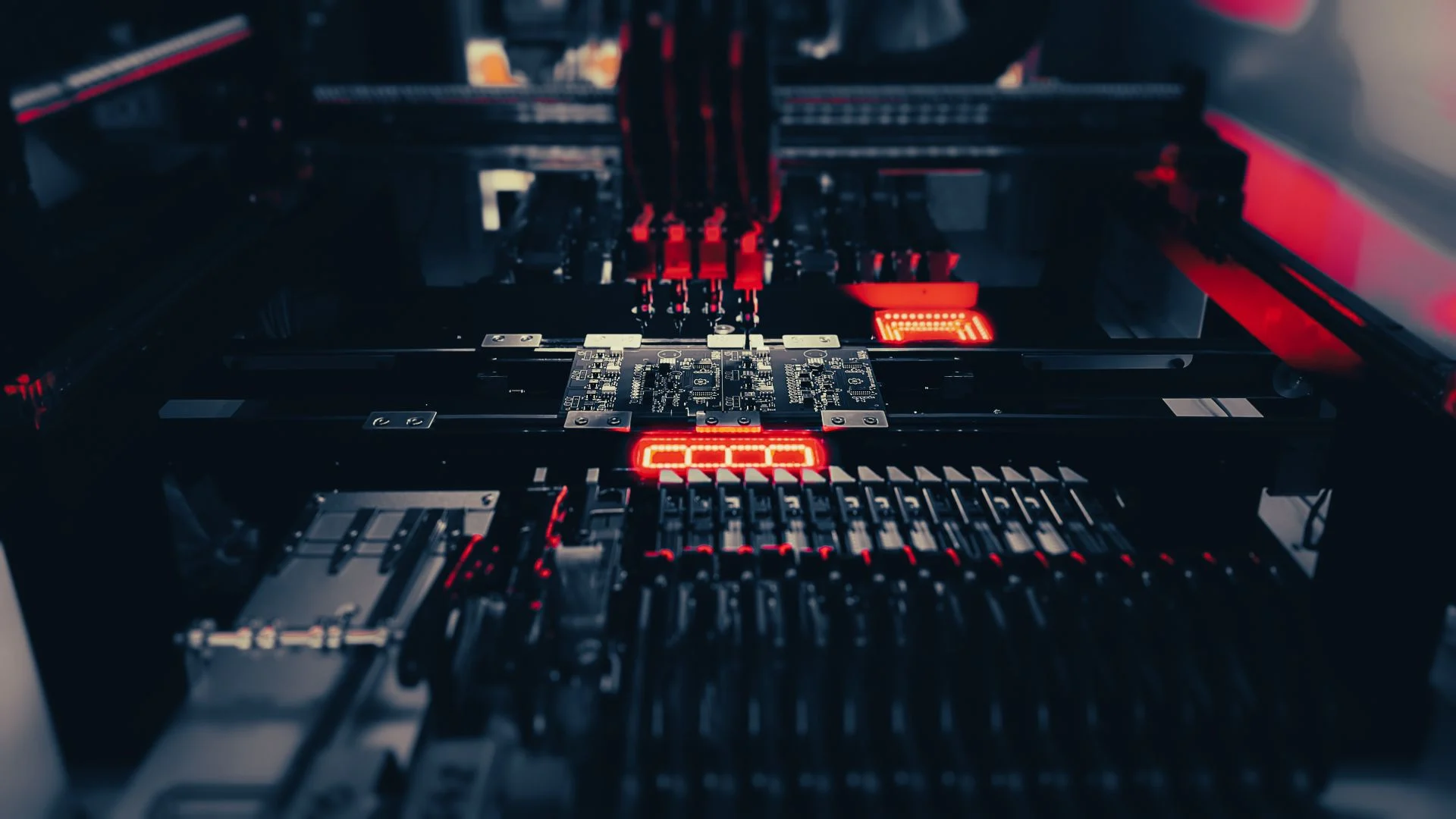

SMT Technology - PCB Assembly

Surface Mount Technology is a standard procedure in electronics circuit assembly today. Many PCB makers lately rely on SMT technology to manufacture their boards. Surface Mount Technology is the process of mounting electronic components to surfaces of PCBs. Surface Mount Technology is different from Plated Through-Hole Technology and the best replacement or option to PTH. With Surface Mount Technology, it’s possible to build even some of the most complex electronic circuit boards with a lot of ease.

By using this technology, you can achieve smaller assemblies with excellent repeatability. All this is due to the high levels of automation and precision that comes with Surface Mount Technology technology. Many makers now use this technology as it enables them to design small PCBs that are lightweight and compact quickly. Better yet, it’s a much faster process compared to through-hole technology. Surface Mount Technology doesn’t call for too much work during the assembly. SMT is a simple process of just picking and placing PCB components on the board.

Advantages of SMT technology

a. Low Manufacturing Cost

b. Improvise Assembly Efficiency

c. Low Assembly Error

d. Better Adaptable for smaller components or high density component requirement

e. Higher Connection Density

f. Lesser Drill Holes for PCB

g. Lower Radiation Emission

h. Better Electromagnetic compatibility (EMC) performance

Do contact us if you have and PCB Assembly or Manufacturing requirements. Let us provide a quote for your reference and comparison.